Introduction of PLA Biodegradable Materials

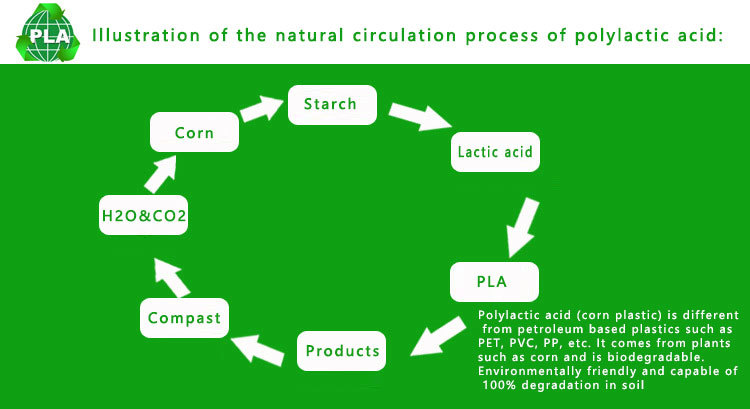

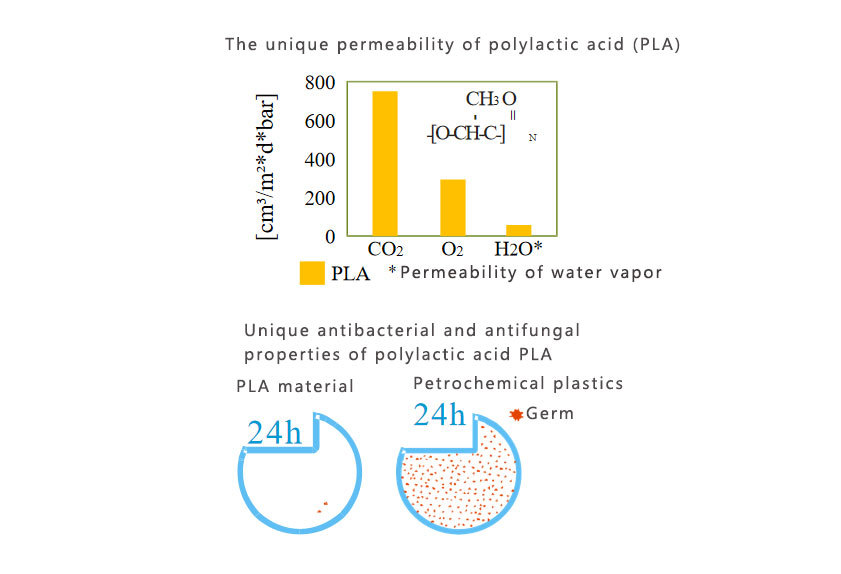

The components of polylactic acid are from renewable resources, like the carbohydrate in cassava, corn, sugarcane and other botany, with good compatibility and degradability as well as unique breathability and natural bacteriostat anti-mildew.

E-mail:

Jianmen Techpoly

Bio-based TPE

- INTRODUCTION

- APPLICATION

- ADVANTAGES

- SPECIFICATIONS

-

-

The components of polylactic acid are from renewable resources, like the carbohydrate in cassava, corn, sugarcane and other botany, with good compatibility and degradability as well as unique breathability and natural bacteriostat anti-mildew.

Antibacterial effect (antibacterial rate);Staphylococcus aureus ≥90% (Level AAA);Escherichia coli ≥75% (Level AAA);

Fermentation tea-leaves(Contrast after indoor reservation for two months)

-

PLA Polylactic Acid PK Traditional Plastics

Name of material PP PC PS Melamine PLA polylactic acid Source of material Petroleum Petroleum Petroleum Tripolycyamamide Starch plants Potential safety hazard Plasticizer Bisphenol A Styrene Formaldehyde Non-toxic and no harm Strength of product *** **** * *** * Usage temperature -20℃~120℃ -20℃~250℃ -5℃~70℃ -20℃~120℃ -20℃~110℃ Microwave oven safety YES YES NO NO YES Dish-washing machine safety YES YES NO NO YES Possible Bisphenol A toxic

Degradation characteristic NO NO NO NO Biodegradation Environmental-protection characteristic Cyclic regeneration Cyclic regeneration Cyclic regeneration Cyclic regeneration Cyclic regeneration Carbon emission while producing

PRODUCT CONSULTATION

Learn about the latest information on Biosphere plastic biodegradants

RELATED PRODUCT

Overall Migration Test with Food Simulants ;Chemical Resistance Test;Liquid Viscosity Test;UV Aging Test;Heat Aging Test;Oil Bleeding Test;

VIEW MORE +

Wood (bamboo) plastic modification has always been one of our main development directions, especially in the field of wood chip modification. Through years of continuous experiments, our company has compared and modified various different wood chip materials, and has made phased progress. Its wood plastic injection molding materials have reached the leading level in China and have applied for national utility model patents.

VIEW MORE +