Biomass PP

Wood (bamboo) plastic modification has always been one of our main development directions, especially in the field of wood chip modification. Through years of continuous experiments, our company has compared and modified various different wood chip materials, and has made phased progress. Its wood plastic injection molding materials have reached the leading level in China and have applied for national utility model patents.

E-mail:

- INTRODUCTION

- APPLICATION

- ADVANTAGES

- SPECIFICATIONS

-

Wood (bamboo) plastic modification has always been one of our main development directions, especially in the field of wood chip modification. Through years of continuous experiments, our company has compared and modified various different wood chip materials, and has made phased progress. Its wood plastic injection molding materials have reached the leading level in China and have applied for national utility model patents.

-

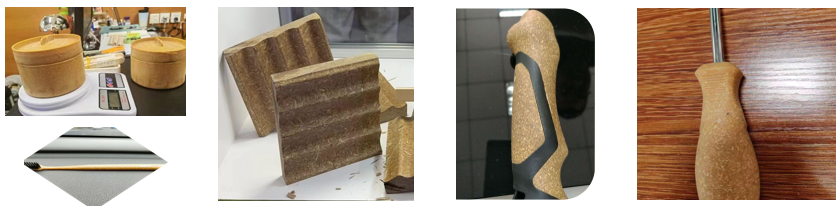

The main applications of environmentally friendly wood plastic PP

1. Outdoor walkways, pavilions, chairs and other urban construction supplies;

2. Building materials such as houses, high-end flooring and building templates;

3. Daily necessities such as toothbrushes, chopsticks, tea cups, etc;

4. Other products such as car interior decoration, pipe materials, and adhesive packaging.

-

a. The wood chips used in the product are collected from primitive forests. The wood chips collected from primitive forests have advantages such as natural fragrance, high glossiness, no pollution, and environmental protection, which are incomparable to ordinary discarded wood chips. The use of wood chips collected from primitive forests can significantly improve the simulation of wood plastic materials.

b. The selected wood chips for the product are sorted, bleached, and pre treated with appropriate coupling agents to enhance their compatibility with polypropylene based non-polar matrices, thereby significantly improving the mechanical properties of wood plastic injection materials such as tensile strength, bending strength, and impact strength.

c. The pre treated wood chips are first compatibilized and then mixed with polypropylene for extrusion granulation. This process can significantly reduce the amount of wood plastic injection molding material. During extrusion, due to temperature and screw shear, the wood chips are burnt.

d. The new product uses an efficient polypropylene modifier, which can effectively improve the whitening phenomenon of polypropylene materials while not reducing their physical and mechanical properties.

e. Bamboo plastic PP also pays attention to the selection of materials. Bamboo chips must be processed from bamboo for at least two years, and other processes are the same as wood plastic processing.

f. High cost-effectiveness, much lower than similar imported products. -

commodity

Wood PP

Test date

2019-5-6

capability item

text method

test data

Data unit

PP material

PP Wood(Bamboo)PP

Basic capability

Density

ASTM-792

0.9

0.86

g/cm3

Melt-flow rate test

ASTM-1238

14

15

g/10min

Mechanical capability

Solidity

ASTM-785

68

D

Tensile modulus of elasticity

GB/T 1040.2-2006

160

148

MPa

Tensile strength

GB/T 1040.2-2006

18

17

MPa

Flexural modulus

GB/T 9341-2008

891

913

MPa

bending strength

GB/T 9341-2008

19

18.7

MPa

PRODUCT CONSULTATION

Learn about the latest information on Biosphere plastic biodegradants

RELATED PRODUCT

Overall Migration Test with Food Simulants ;Chemical Resistance Test;Liquid Viscosity Test;UV Aging Test;Heat Aging Test;Oil Bleeding Test;

VIEW MORE +

Wood (bamboo) plastic modification has always been one of our main development directions, especially in the field of wood chip modification. Through years of continuous experiments, our company has compared and modified various different wood chip materials, and has made phased progress. Its wood plastic injection molding materials have reached the leading level in China and have applied for national utility model patents.

VIEW MORE +