Introduction of biodegradation

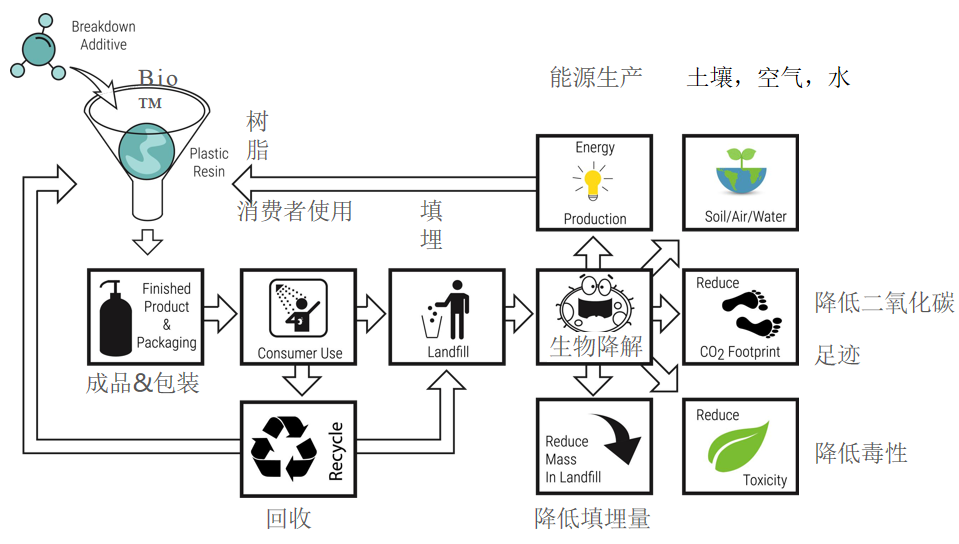

Bio™ is an organic additive used to accelerate the biodegradation of plastic, rubber and PS foam products in landfills filled with active anaerobic organisms.Bio™ is mixed with existing plastic materials, directly blended and then enters the extruder through the hopper. You can also use a fixed weighing system to add and use online proportionally

E-mail:

Jianmen Techpoly

Bio-based TPE

- INTRODUCTION

- APPLICATION

- ADVANTAGES

- SPECIFICATIONS

-

Bio™ is an organic additive used to accelerate the biodegradation of plastic, rubber and PS foam products in landfills filled with active anaerobic organisms.

Bio™ is mixed with existing plastic materials, directly blended and then enters the extruder through the hopper. You can also use a fixed weighing system to add and use online proportionally

Bio™ is added at a ratio of 2-4% according to different plastic types and models.

Bio™ can be applied to EVA, EVOH, HDPE, LDPE, LLDPE, nylon, PET, PETG, polycarbonate

And PP, we are currently committed to the research and development of Styrofoam additives and a 100% brand new resin called Bio301. Bio301 will completely replace plastic.

Bio™ can be applied to man-made fibers such as polyester, elastane, vinyl propylene and nylon. The synthetic shirts we wear can be fully biodegradable by adding Bio™.

Bio™ meets FDA and EU standards and EINECS, REACH, CFIA safety in food contact. Bio™ products can be recycled multiple times.

-

Bio™ introduces plastic into a biodegradable anaerobic environment through a series of chemical and biological procedures. This procedure is called bioabsorption/assimilation.

Bio™ allows microorganisms to create a biofilm structure to penetrate plastics. This biofilm is only formed in the absence of oxygen, such as in landfills and deep seas.

Bio™ can help expand the intermolecular structure of plastics and create more space for bacteria/microbes. At the same time, it sends out chemical signals that attract bacteria to form large-scale polymer chains, attracting certain types of bacteria to use plastic as their food chain.

Bio™ is currently promoting the degradation of chemical bonds to consolidate the anaerobic and biodegradation rate of Bio™ compared to traditional plastics.

Bio™ allows plastic products to produce only water, carbon dioxide, biogas and humus (organic matter). This is the same as the biodegradation process of organic matter and residues.

-

Bio™ products are made of traditional plastic injected with anaerobic organic additives. The additives introduce the plastic into the biodegradation stage through chemical activities caused by bacteria, leaving only natural gas and biological energy in the end.

Here are the facts:

Bio™ products are recyclable and can be recycled multiple times without affecting the existing recycling system

Specially developed for anaerobic landfill for biodegradation and does not require oxygen

No feedback on product quality issues, appearance, strength, touch, stability and lifespan have not changed, just like traditional plastics

Set biodegradation within 1-5 years to release methane in a controlled manner to be reused through the bioreactor or to be discharged and captured for clean energy.

No need to make any changes to the current manufacturing machinery and incur costs. Bio™ is a fast and convenient technology to add on demand.

Bio™ complies with FDA and EU, Toxic, Substance, Control, Act (USA), EINECS, CFIA and other standards.

Category

Life

Recyclable

landfill degradation

Compost degradation

Residue

PET

NO definition

Yes

Never

Never

plastic

PLA

1-6 Months

NO

Little

3-6 Months

energy and natural gas

STARCH

1-4 Months

NO

Never

30-180 Days

carbon dioxide and energy

Photodegradation

2-4 Months

NO

Never

3 Months-5 Years

Drill, pot and resin

Oxygen degradation

2-6 Months

NO

Never

3 Months-5 Years

CO, bioenergetics and other toxic metals

*The required time is related to the storage of materials, quantity, and real-time quality of micro organic matter. 1-5 years are estimated and a large number of actual test results are obtained.

-

This test method determines the level and efficiency of biodegradation of plastic materials in an anaerobic environment (ASTM D5511).

Inoculum: from the anaerobic digestion of household waste. This usually comes from the sediment of a certain proportion of solid matter mixed in the composting equipment of the water treatment plant. This inoculum contains methanogenic bacteria that can also be found in landfills. The control device and sample plate of the sediment are all materials used for ASTM D5511 testing

Negative control: untreated material that is the same or similar to the test material. This is usually not included in the test because the material is not representative of degradation.

Positive control: the cellulose product being tested. Positive control ensures biodegradation within 30 days, such as a piece of paper. Once the cellulose shows 100% biodegradation, the test is stopped and a comparison with the BIO™ sample is made.

Sample: material processed with BIO™

After the initial combustion aerobic activity, oxygen is consumed in the culture vessel. Then, anaerobic bacteria began to multiply and settle in the container. As these bacteria begin to use carbon in the test sample, they produce carbonaceous gases such as CO2 (carbon gas) and CH4 (methane gas). Measure these gases every day and record the results carefully.

The molar weight of the total gas produced by the test sample is calculated and compared with the carbon weight of the original sample, and the biodegradation percentage of the sample can be determined.

result

Carbon gas recovery (G) Inference(G) Biodegradation% Sample 20150926CC-1 (BIO) 1.59 21.4 7.4 Positive control (cellulose) 7.24 8.8 82.3 After 3 days, the plastic containing BIO additives under the conditions listed in the ASTM D-5511 method showed 7.4% biodegradation after a 30-day test

All tests are carried out at Northeast Laboratories, In. testing facility.

ASTM D-5511 test Regarding: Biosphere Sample (690 Days)

Inculum Negative Positive PE-CrossLinkedFoam(690 days) PE-Tshirt Bags(69odays) PS-Coffee Lids(69 0days) Cumulative Gas Volume (mL) 5070.0 4753.8 21629.6 13363.7 17118.0 24205.8 Percent CH4(%) 48.3 57.7 46.6 50.4 50.3 50.7 Volume CH4(mL) 2448.8 2742.8 10075.0 6734.5 8605.0 12263.1 Mass CH4(g) 1.8 2.0 7.2 4.8 6.2 8.8 Percent CO2(%) 48.3 57.7 46.6 50.7 53.0 51.5 Volume CO2(mL) 2448.8 2742.8 10075.0 6776.1 9079.2 12466.1 Mass co2 (g) 4.8 5.4 19.8 13.3 17.8 24.5 Sample Mass (g) 1000.0 10.0 25.0 6.0 10.0 20.0 TheoreticalSample Mass(g) 0.0 8.6 11.1 5.1 8.6 17.1 Biodegraded Mass (g) 2.6 2.9 10.8 7.2 9.5 13.3 Percent Biodegraded(%) n/a 3.7 73.9 89.7 79.9 62.0

PRODUCT CONSULTATION

Learn about the latest information on Biosphere plastic biodegradants

RELATED PRODUCT

Overall Migration Test with Food Simulants ;Chemical Resistance Test;Liquid Viscosity Test;UV Aging Test;Heat Aging Test;Oil Bleeding Test;

VIEW MORE +

Wood (bamboo) plastic modification has always been one of our main development directions, especially in the field of wood chip modification. Through years of continuous experiments, our company has compared and modified various different wood chip materials, and has made phased progress. Its wood plastic injection molding materials have reached the leading level in China and have applied for national utility model patents.

VIEW MORE +