Bio-based PE

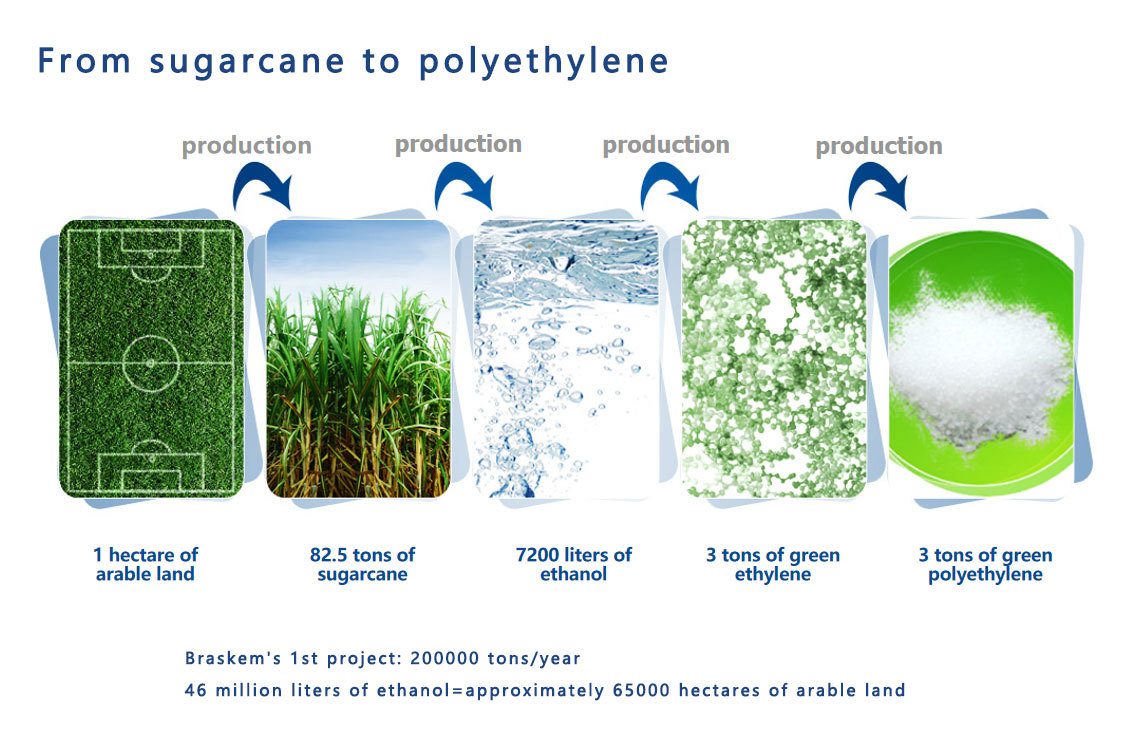

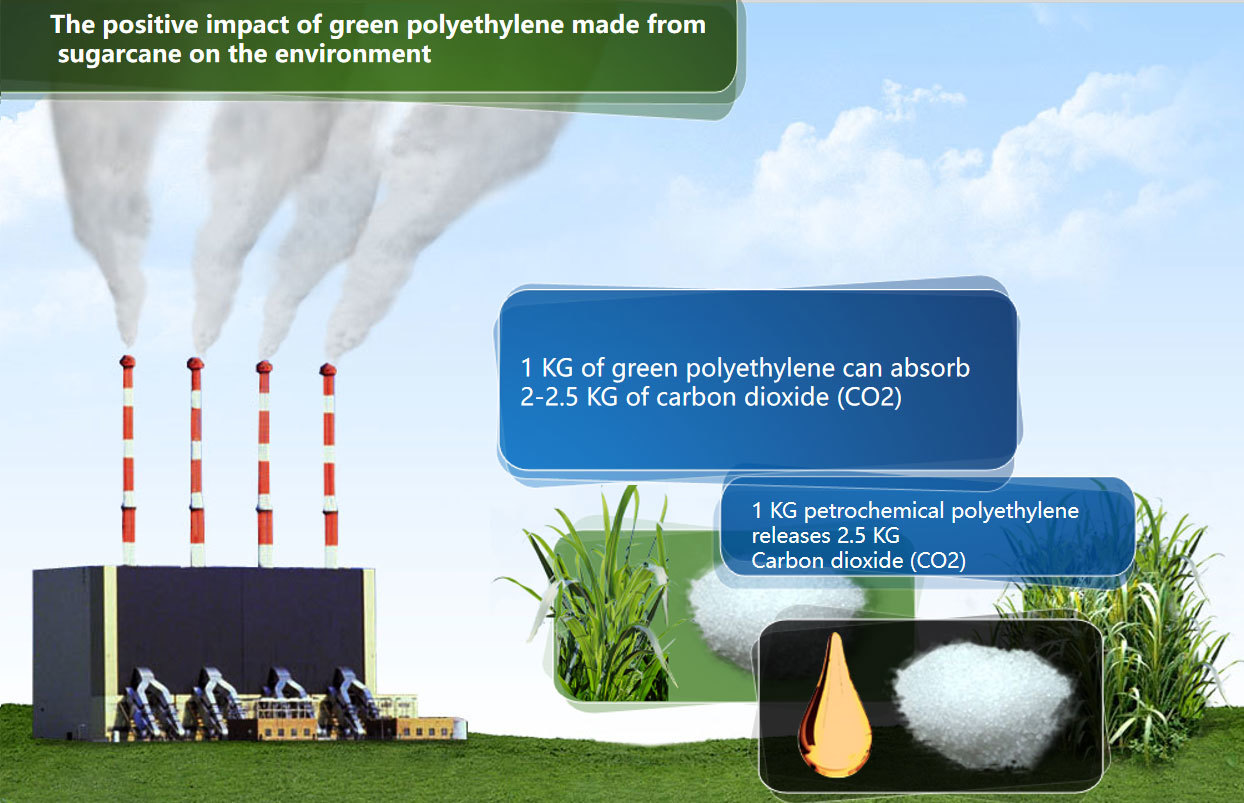

The finished products produced by green polyethylene are exactly the same as those produced by traditional petrochemical polyethylene

E-mail:

- INTRODUCTION

- APPLICATION

- ADVANTAGES

- SPECIFICATIONS

-

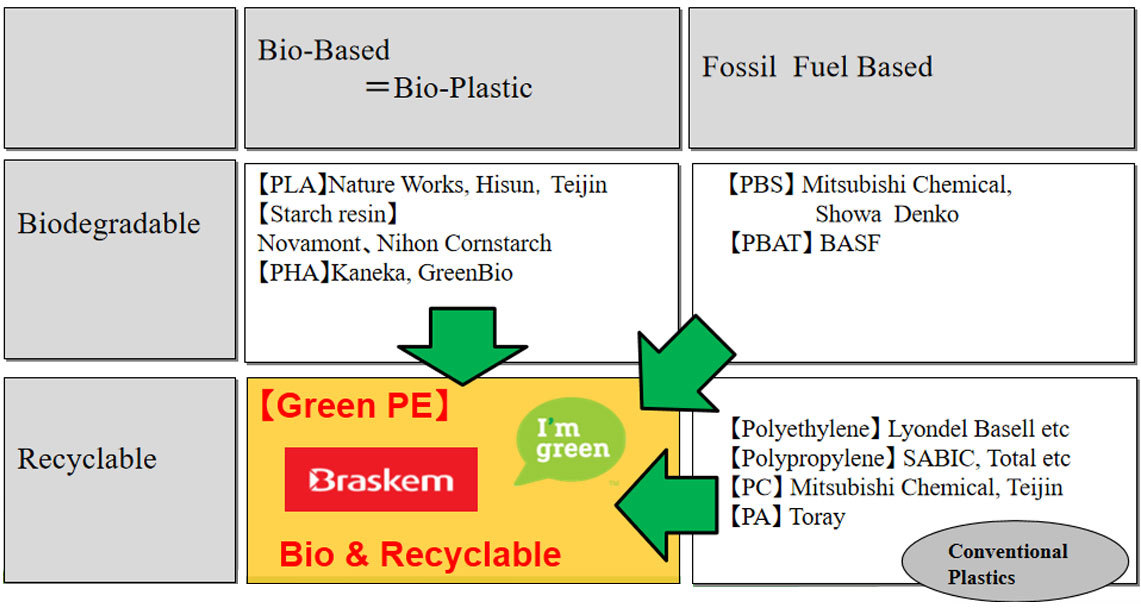

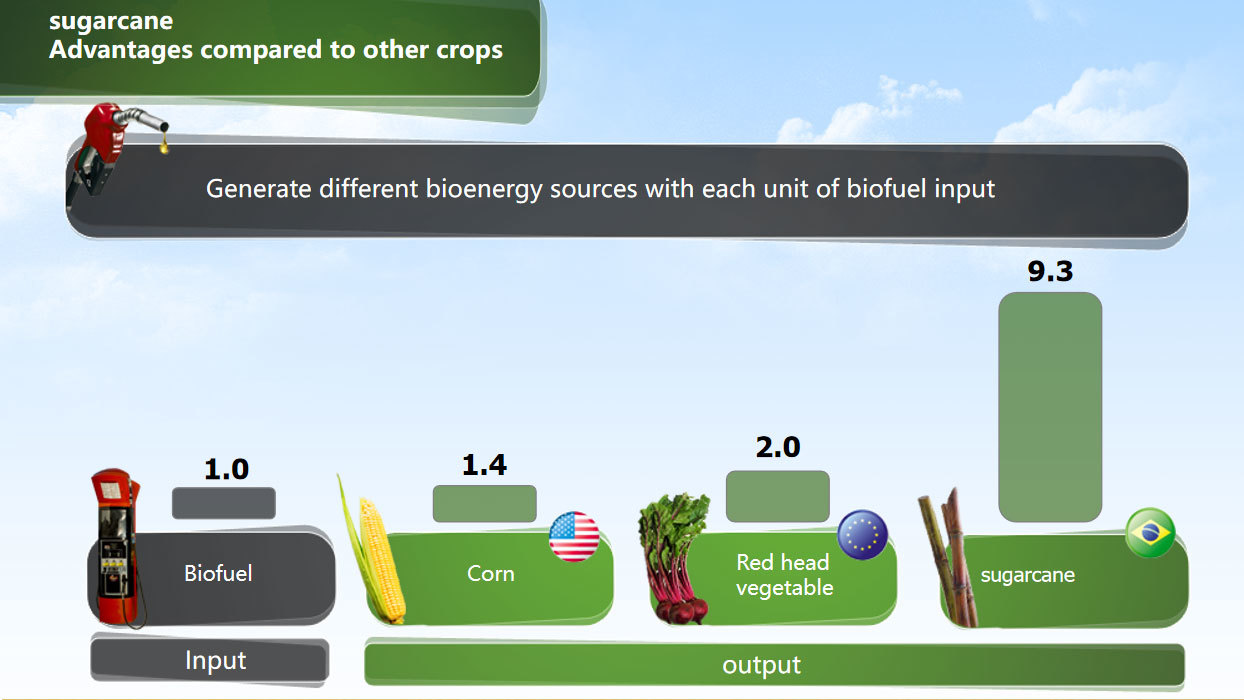

The trend of plastics has changed from fossil plastics to bio based, as well as biodegradable plastics to recyclable.

-

JiangMen Tech-Poly

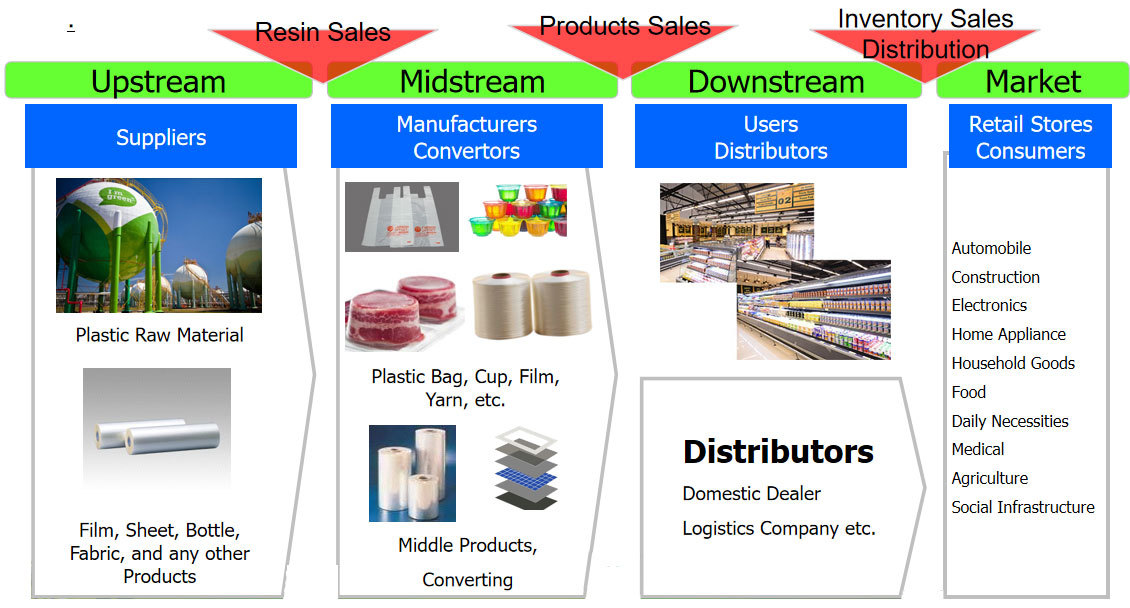

✓handle more than 1,500KMT/y of plastic resin all over the world,

✓create Value Chain among Suppliers, Manufacturers and Users.

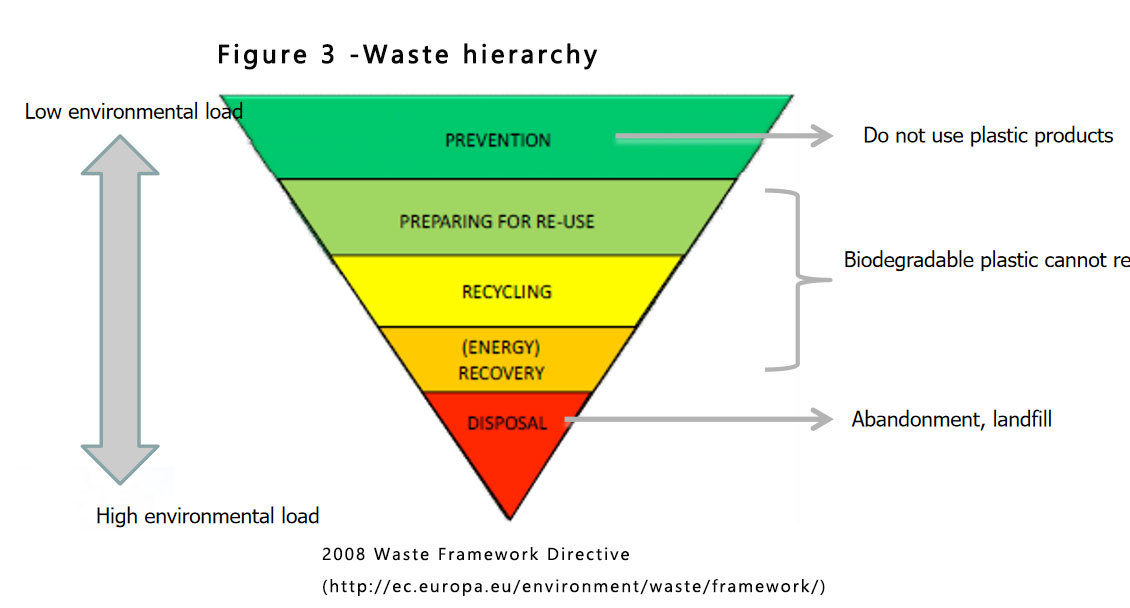

The EU Parliament has a regulation on plastic products, which states that it is best not to use plastic products for the sake of environmental protection.

But behind that regulation lies the low recycling rate of plastic products in Europe and America.

Increasing the reuse rate of plastics is the most important goal of Brand Owners in Europe and America.

-

-

HDPE Model List

HDPE

Film

Injection

Blow

Monofilamentl

ltem

Testing Method

Unit

SGM9450F

SHA7260

SHC7260

SHD7255LS-L

SGE7252

SGF4950

SGF4960

SGD4960

SHE150

MFR(190/21.6)

D1238

g/10min

9.3

28

28

50

MFR(190/21.6)

D1238

g/10min

20

7.2

4.5

2.2

0.34

0.34

0.6

1

MFR(190/5)

D1238

g/10min

0.33

Density

D792

g/cm³

0.952

0.955

0.959

0.954

0.953

0.956

0.961

0.962

0.948

Tensile Stress.at Yield

D638

MPa

29

30

27

(ISO 527-2)24

28

32

33

28

Tensile Stress at Yield(film MD/TD)

D882

MPa

40/30

Tensile Stress at Break

D638

MPa

(ISO 527-2)17

31

35

25

40

Tensile Stress at Break(film MD/TD)

D882

MPa

40/50

Elongation at Yield

D638

%

7.2

7.5

(ISO 527-2)10

Elongation at Yield(film MD/TD)

D882

%

Elongation at Break

D638

%

(D882 MD620/TD680)

(ISO 527-2)933

Tensile Secant Modulus at 1%(film MD/TD)

D882

MPa

Flexural Module 1% se cant

D790

MPa

1350

1350

1270

(ISO 178)

1060

1210

1508

1280

Hardness, shore D/15

D2240

64

64

63

63

64

62

Notched lzod Impact Resistance at 23℃

D256

J/m

25

35

45

145

210

84

Impact Resistance by Freefalling Dart(film 12um)

D1709

g-F50

210

Environmental Stress Cracking Resistance(10%)

D1963

h/F50

69

20

17

Environmental Stress Cracking Resistance(100%)

D1963

h/F50

<4

<4

<5

55

19

Heat Defrection Temperature(0.455MPa)

D648

℃

74

76

74

75

79

75

76

Vicat Softening Point at 10N

D1525

℃

124

126

127

129

129

128

128

Min imum biobased content

D6866

%

96

94.5

94.5

94.5

87

96

96

96

94.5

Main Application and Advantage

blow filmgeneral bagwide moler mass bimodal

housewarespails,cap

narrow mo ler masshigh hardness industrial container low warpage

high hardnessbins, box Light stabilizer UV absorber

high stress-crac king resistance

cap, closure bimodalCopolymerbalanced impact-stiffness,Bottle bimodal

Homohigh impact-residence, container bimodal

Homo stiffness bottle,cosmetics bimodal

Copoly mer(butene-1)antioxidant processing agent raschel

LLPE Model List

LLDPE

Film

Item

Testing Method

Unit

SLH118

SLH218

SLL318

SLL118/21

SLH0820/30AF

MFR(190/2.16)

D1238

g/10min

1

2.3

2.7

1

0.8

Density

D792

g/cm3

0.916

0.916

0.918

0.918

0.92

Haze

D1003

%

24

60

61

34

35

Gloss (Angle 60° )

D2457

%

69

17

19

47

49

Tensile Stress at Break MD/TD)

D882

MPa

40/40

40/40

30/30

40/30

50/40

Elongation at Break(MD/TD)

D638

%

1080/1360

1170/1500

1220/1440

1070/1340

950/1180

Flexural Module, 1% secant

D882

MPa

200/210

210/240

180/200

210/230

170/180

Dart Drop Impact

D1709

gF/50%f

150

110

90

130

170

Elmendorf Tear Strength(MD/TD)

D1922

KgF/cm

300/500

240/520

120/340

180/400

270/500

Minimum biobased content

D6686

%

84

84

87

87

84

Main Application and Advantage

blow film MpipeC6, low gel copolymer(Hexcne-1)Spherilene

cast filmstretch film,cable low gel C6, copolymer(Hexcne)Spherilene

cast filmstretch film,cable good seal, process copolymer(Butene-1)Spherilene

blow film au to matic package SLL118+additive Slip Agent(mid) Anti Block Agent(mid

blow filmlami, heavy duty bagno SA, AB(high)Processing Agent(mid)C6,copolymer(Hexene)

LDPE Model List

LDPE

Extrusion coating

Injection

ltem

Testing Method

Unit

SBC818

SBC818R50

STN7006

SPB208

SPB208

SPB608

MFR(190/21.6)

D1238

g/10min

MFR(190/21.6)

D1238

g/10min

8.1

8.1

0.6

0.6

22

30

MFR(190/5)

D1238

g/10min

Density

D792

g/cm3

0.918

0.918

0.924

0.924

0.923

0.915

Ultimate Strength(MT/TD/td)

D882

MPa

Tensile Stress at Break

D638

MPa

10

8

Tensile Stress at Break(MD/TD)

D882

MPa

25/20

25/20

25/20

25/20

Tensile Stress at Yield

D638

MPa

6

8

Elongation at Break

D638

%

139

390

Elongation at Break(ND/TD)

D882

%

380/870

380/870

380/870

380/870

2%Secont Modulus(MD/TD)

D882

MPa

140/170

140/170

Flexural Module 1% secant

D882

MPa

70

70

Flexural Module 1% secant

D790

MPa

700

450

Dart Drop lmpact

D1709

g/F50

64

64

170

170

Elmendorf Tear Strength

D1922

gF

NDb/56

NDb/56

63

Elmendorf Tear Strength(MD/TD)

D1922

gF

310/250

310/250

Hzze

D1003

%

8

8

8.5

9

Gloss (Angle45)

D2457

%

60

60

Gloss (Angle60)

D2457

%

76

76

86

84

Shore D Hardness

D2240

-

42

39

Vicat Softening Point at 10N

D1525

℃

87

79

Min imum biobased content

D6866

%

95

95

95

95

95

95

Main Application and Advantage

Extrusion coating Injection-Masterbaches Additive free Autoclave

Extrusion coating Injection*Masterbaches Additive free

Coextruded films Packageing for cheese,ham Additive free low gel

Coextruded films Packageing for cheese,ham Slip(Mid)-Anti blockMid) Low gel

Covers and injection parts MasterbatchesAttive free Autoclave - Good flexibility

Covers and injection parts MasterbatchesAttive free Autoclave - Good flexibility

HDPE Model List

LDPE

Film

ltem

Testing Method

Unit

SBF0323HC

SBF0323/12HC

SBE853

SBE853/72

SPB681

SPB681/59

MFR(190/21.6)

D1238

g/10min

MFR(190/21.6)

D1238

g/10min

0.32

0.32

2.7

2.7

3.8

3.8

MFR(190/5)

D1238

g/10min

Density

D792

g/cm3

0.923

0.923

0.923

0.923

0.922

0.922

Ultimate Strength(MT/TD/td)

D882

MPa

30/20

30/20

Tensile Stress at Break

D638

MPa

Tensile Stress at Break(MD/TD)

D882

MPa

40/30

40/30

40/20

40/20

Tensile Stress at Yield

D638

MPa

Elongation at Break

D638

%

Elongation at Break(ND/TD)

D882

%

390/1040

390/1040

300/280

300/280

370/1070

370/1070

2%Secont Modulus(MD/TD)

D882

MPa

Flexural Module 1% secant

D882

MPa

Flexural Module 1% secant

D790

MPa

Dart Drop lmpact

D1709

g/F50

100

100

50

70

60

60

Elmendorf Tear Strength

D1922

gF

NDb/90

NDb/100

NDb/100

NDb/100

NDb/100

NDb/100

Elmendorf Tear Strength(MD/TD)

D1922

gF

Hzze

D1003

%

10

11

5

5

4

4

Gloss (Angle45)

D2457

%

60

60

Gloss (Angle60)

D2457

%

72

83

113

112

120

112

Shore D Hardness

D2240

-

Vicat Softening Point at 10N

D1525

℃

Min imum biobased content

D6866

%

95

95

95

95

95

95

Main Application and Advantage

Heavy duty bagsShrink filmsAdditive freeTubular

Aoto packaging for products Shrink films Slip(Mid)Anti blockMid)Tubular

Blown films Diapers Additive freeTubular-Low gel

Blown films Lamination filmSlip(Mid)-Anti block(Mid)Tubular-Low gel

LLDPE/HDPE blends Blown/cast film·Injection Additive free Tubular

Blown filmslamination film SlipHigh)·Anti blockMid)Tubular

PRODUCT CONSULTATION

Learn about the latest information on Biosphere plastic biodegradants

RELATED PRODUCT

Overall Migration Test with Food Simulants ;Chemical Resistance Test;Liquid Viscosity Test;UV Aging Test;Heat Aging Test;Oil Bleeding Test;

VIEW MORE +

Wood (bamboo) plastic modification has always been one of our main development directions, especially in the field of wood chip modification. Through years of continuous experiments, our company has compared and modified various different wood chip materials, and has made phased progress. Its wood plastic injection molding materials have reached the leading level in China and have applied for national utility model patents.

VIEW MORE +