Bio-based EVA

The posstblity of using this product for a specliflc purpose may change according to the country and should be analyzed by the interested party. Broskem does not guarantae the possiblity of using the product with other matarials for the desired application. pleste check tha RiS or contoct Broskem for specilfic rogulatory informaton.

E-mail:

- INTRODUCTION

- APPLICATION

- ADVANTAGES

- SPECIFICATIONS

-

-

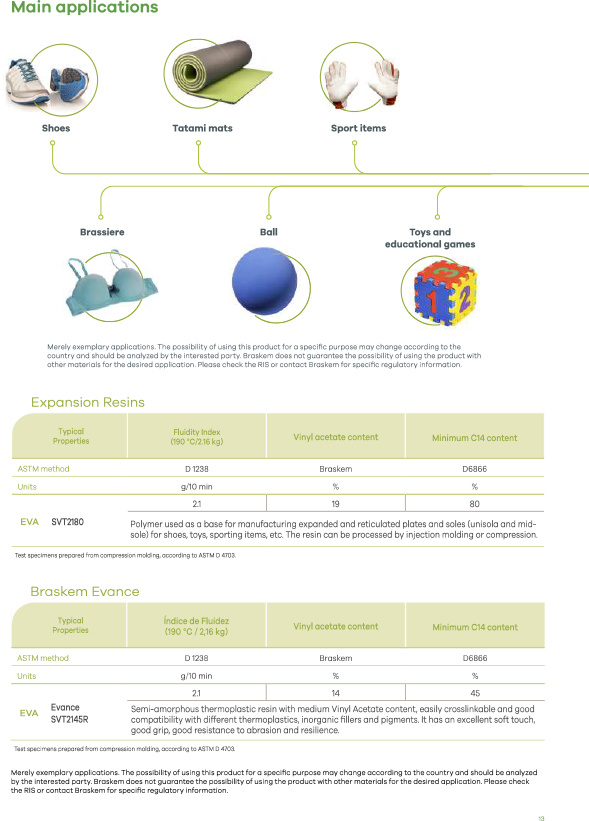

The l'm green"" bio-based EVA is ideal to applications such as: shoes, adhesives,toys, wires& cables,tatami mats and foams in general.

The support of Braskem's technical teams duringthe development of the products guarantees ashorter approval time for Customers and a rangeof high renewable content in the final products.

-

Expansion Resins

PropertiesTypicol

Fluidity lndex(190 C/2.16 kg)

Vinyl acetate content

Minimum C14 content

ASTMmethod

D1238

Broskem

D6866

Unts

g/10min

%

%

EVA SVT2180

2.1

19

90

Polymer used as a base for manufacturing expanded and reticulated plates and soles (unisola and mld-sole) for shoes,toys, sporting items, etc. The resin can be processed by injection molding or compression

Braskem Evance

PropertiesTypicol

Fluidity lndex(190 C/2.16 kg)

Vinyl acetate content

Minimum C14 content

ASTMmethod

D1238

Broskem

D6866

Unts

g/10min

%

%

EVA SVT2180

2.1

14

45

semi-amorphous thermoplastic resin with medium vinyl Acetate content, easily crasslinkable and goodcompatibility with different thermoplastics, inorganic fillers and pigments. t has an axcellent soft touch,good grip. good resistance to albrasion and resilience.

PRODUCT CONSULTATION

Learn about the latest information on Biosphere plastic biodegradants

RELATED PRODUCT

Overall Migration Test with Food Simulants ;Chemical Resistance Test;Liquid Viscosity Test;UV Aging Test;Heat Aging Test;Oil Bleeding Test;

VIEW MORE +

Wood (bamboo) plastic modification has always been one of our main development directions, especially in the field of wood chip modification. Through years of continuous experiments, our company has compared and modified various different wood chip materials, and has made phased progress. Its wood plastic injection molding materials have reached the leading level in China and have applied for national utility model patents.

VIEW MORE +